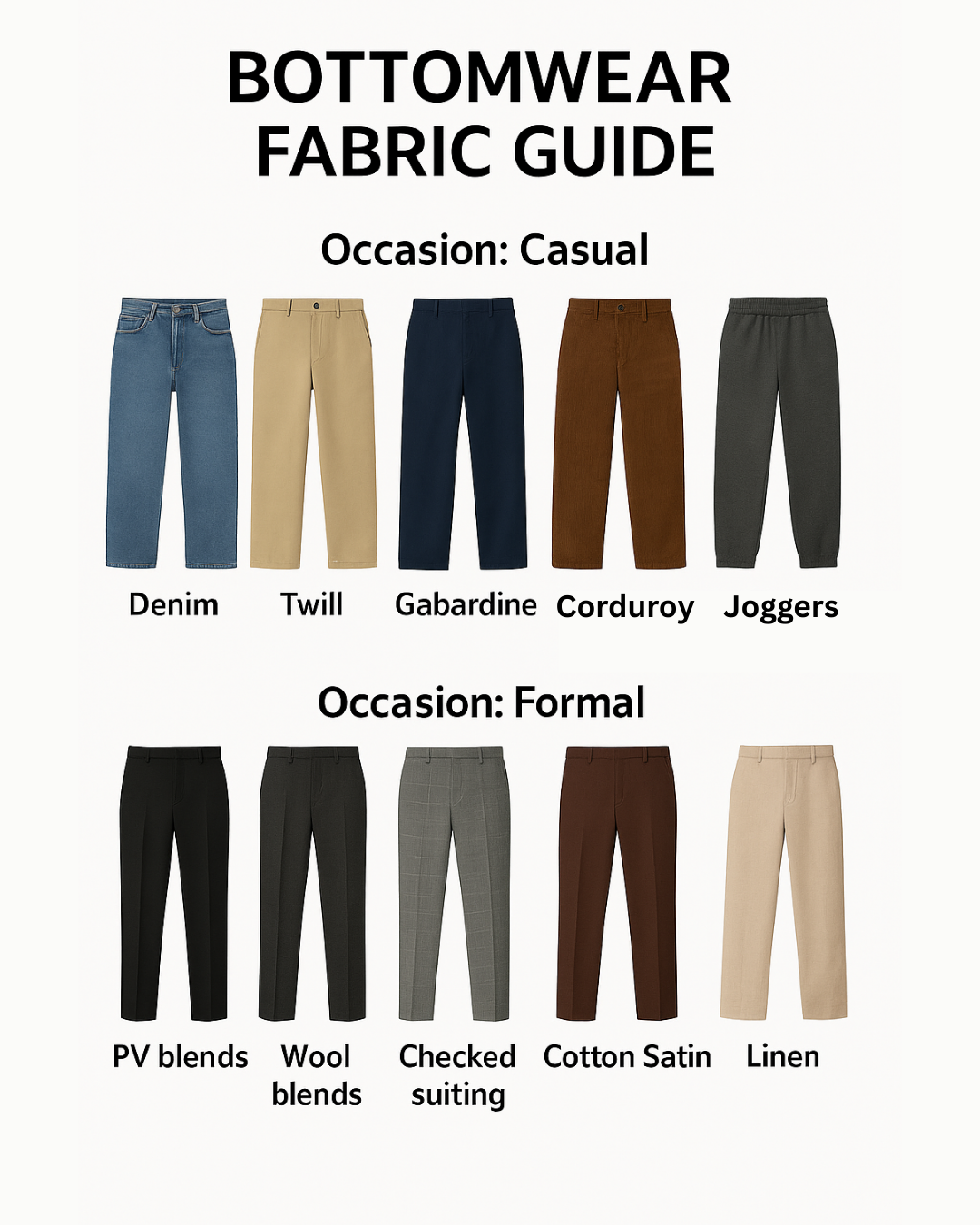

Choosing the Right Fabric for Bottomwear: A Guide for Brands & Buyers

Bottomwear takes a beating.

From factory floors and school corridors to retail showrooms, the right fabric needs to balance structure, comfort, durability, and cost while meeting your brand’s aesthetic and sustainability goals. This guide breaks down how to choose the best bottomwear fabrics such as trousers, chinos, workwear, uniforms, skirts, shorts and lightweight jackets, and how Desai Textiles partners with brands to deliver consistent, production-ready fabric.

What counts as “bottomwear” fabric?

Bottom weight or bottomwear fabrics are medium to heavy textiles designed to withstand frequent movement and abrasion. They are typically used for pants, skirts, shorts, jeans and light jackets. They are chosen for strength, recovery, and opacity, and often have a structured drape that holds the garment’s shape.

Key takeaway: If the fabric must bend, stretch, sit, and still look neat hours later, you are in bottomwear territory.

The 5 variables that matter most

List of Services

-

Fiber & BlendItem Link List Item 1

• 100% Cotton: Breathable, natural handfeel; ideal for chinos and casual trousers.

• Cotton and Poly Blends: Greater wrinkle resistance, faster drying, better price stability.

• Cotton and Lycra (Elastane/Spandex): Adds comfort stretch and recovery, crucial for modern fit profiles.

• Tencel or Lyocell Blends: Smooth drape, moisture management, elevated handfeel.

• Linen and Blends: Natural look, breathable; blending helps control wrinkling.

• Polyester, Viscose and Other Blends: Useful for uniforms and workwear requiring stability and easy care.

Desai Textiles manufactures across this full spectrum including cotton, cotton-poly, Tencel or Lyocell, linen and blends, with strong capability in stretch constructions.

-

Weave & ConstructionItem Link List Item 2

• Twill (diagonal ribs): The classic bottomwear weave, strong and versatile. Think denim, chino, drill.

• Gabardine (tight twill): Durable, crisp face, great for tailored trousers and uniforms.

• Canvas or Duck (plain or basket): Rugged and structured, ideal for workwear and utility.

• Corduroy or Moleskin: Seasonal and textural options for fall and winter collections.

Tip: For chinos, specify a fine twill with controlled luster. For workwear, consider drill, gabardine or canvas with higher abrasion resistance.

-

Fabric Weight (GSM/oz)Item Link List Item 3

Heavier weights typically enhance durability, structure, and opacity. Assess by end use such as daily office wear, industrial uniforms or fashion-forward silhouettes. Always review weight in GSM or oz/yd² alongside weave and fiber, as weight alone does not guarantee performance.

-

Stretch, Recovery & ComfortItem Link List Item 4

Small percentages of elastane or spandex in cotton or blends improve movement and shape retention. This is critical for slim and tapered fits, or for long wear times. If you need comfort without significant elastane, talk to your mill about mechanical stretch options.

-

Finishing & HandfeelItem Link

Choose finishes that align with performance targets such as easy care, softening, dimensional stability, or stain release. For uniforms and high-rotation garments, prioritize wrinkle resistance and pilling control. Your lab protocol should validate these.

Match the fabric to the job

- Chinos or Office Trousers

Fine cotton twill, cotton-lycra, or lyocell-cotton blends for drape and comfort. - Uniforms and Workwear

Drill, gabardine, or canvas, often in blends for easy care and stability. - Casual Bottoms and Shorts

Medium twill, canvas, or light gabardine; optional stretch for mobility. - Light Jackets and Skirts

Bottom-weight twill, canvas or gabardine for structure and shape.

Why brands choose Desai Textiles for bottomwear

• End-to-end capability in bottom weights including twills, drills, gabardine, canvas and structured dobbies delivered in cotton, blends and stretch variants.

• Modern shuttleless weaving (Airjet and Rapier) for speed, consistency and fabric quality.

• Design and product development strengths to tune handfeel, drape and performance to your specification.

• Cluster advantage: Based in Ichalkaranji, India’s high-output weaving hub, enabling agile sourcing and scale.

From your brief to bulk: We align on fiber, weave, weight, stretch and finish; develop strike-offs quickly; and deliver consistent production lots with the repeatability buyers need.

What we make (at a glance)

List of Services

-

Constructions:Item Link List Item 1

- Dobbies and structures

- Twill, Drill, Gabardine, Canvas

- Stretch fabrics for comfort and performance

-

Fiber content:Item Link List Item 2

- 100% Cotton

- Cotton–Polyester Blends

- Tencel or Lyocell Blends

- Linen and Blends

- Polyester–Viscose and Others

-

End uses:Item Link List Item 3

Bottom weights, Joggers, Shorts, Loose mid-weight shirts, Kurtas, Industrial fabrics, Jackets.

What is a bottomwear or bottom weight fabric?

A medium-to-heavy fabric engineered for pants, skirts, shorts and light jackets, built for durability, structure and opacity.

Which weaves are best for trousers?

Twill including gabardine and drill is the classic choice. Canvas or duck is common for workwear and utility.

Should I choose stretch?

For slim or tapered fits or long wear times, a small amount of elastane improves comfort and shape retention.

Does GSM matter?

Yes. Weight influences structure, durability and opacity but should be evaluated together with weave, fiber and finishing.

Work with Desai Textiles

If you are launching chinos, uniforms, utility wear or seasonal bottoms, our team can help you lock the right fiber, weave, weight and finish and scale it with confidence.

Talk to our product team. Specify your end use, handfeel and finish targets. We will share recommended constructions, lead times and strike-off options.